Odawara lacquer ware was designated as a traditional craft in 1984 by the Ministry of Economy, Trade and Industry. What sets Odawara lacquer apart other lacquer craft is its lack of vivid colors and abundant decorations. Rather, it focuses on making the natural wood shine through and emphasizes on the raw, natural beauty of the materials by using transparent lacquer that brings out the natural grain of the wood. In some cases, red tints are used to create an ever bolder focus on the woods natural patterns. It is furthermore characterized by its longevity, withstanding water, acids, temperature changes and alcohol, and the beautiful shine that intensifies the more you use the item.

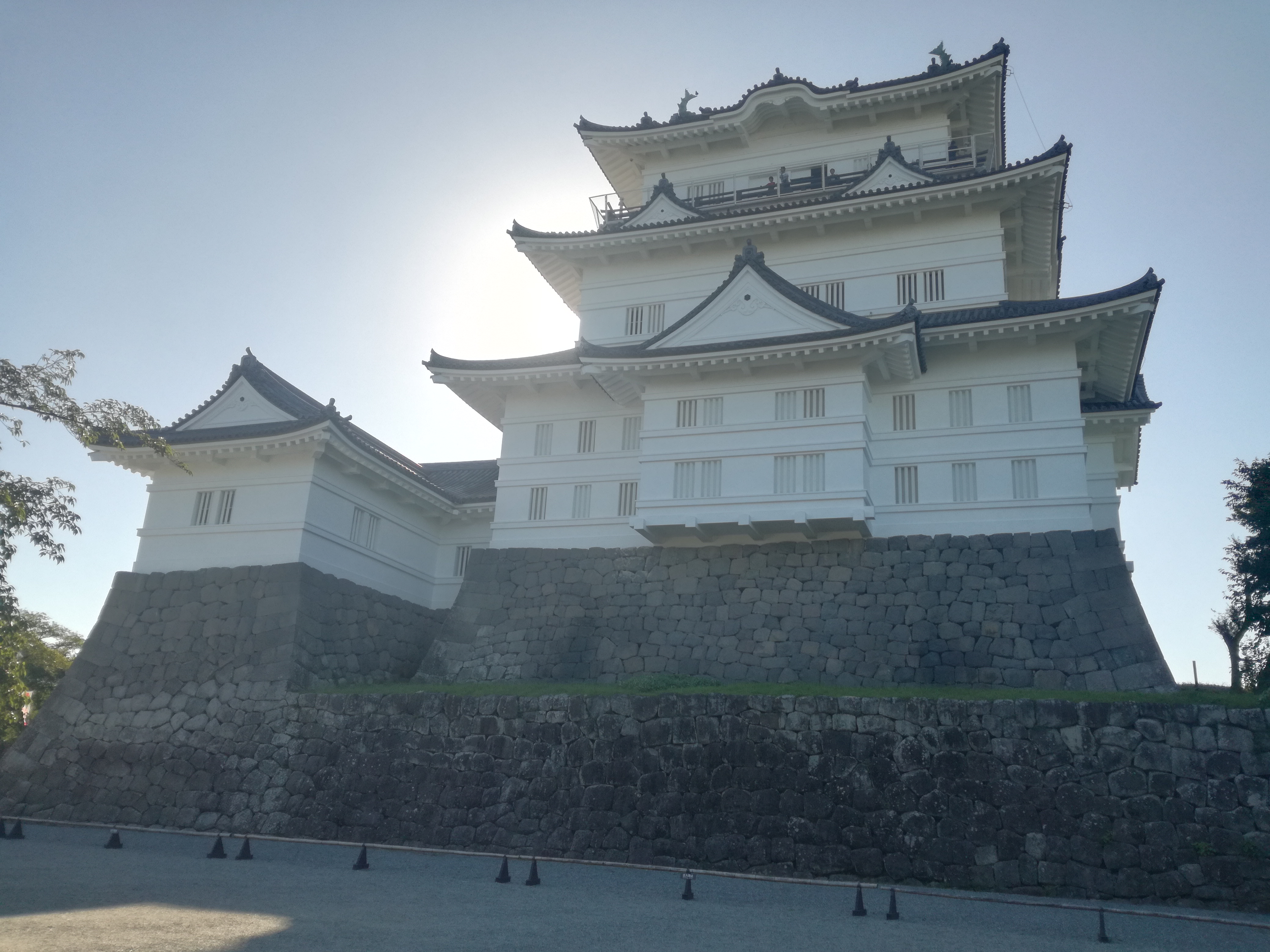

The craft originated during the Muromachi Era (1338 – 1573) when Odawara-based craftsmen started collecting abundant, high-quality wooden lumber resources from the mountainous regions in Hakone.

Under Hōjō Ujiyasu, the third generation of the Hōjō warrior clan whose family controlled much of the Kanto region in Japan, they developed their skills and started to create beautiful lacquerware.

Ujiyasu invited lacquerers from all over Japan to come together and advance the lacquer production techniques with Odawara functioning as a production hub due to its advantageous geographical position. During this time the “Irourushi” technique, which covers wood with red or black lacquer, also took off.

During the Edo period 1603-1867 lacquerware artisans expanded their skills to the decoration of armors and weapons, as well as practical use items such as trays and bowls, which got exported in large quantities to Samurai and wealthy families in Edo (now Tokyo). Some of these items are still preserved today in the Hojo clan’s family temple in Hakone.

ISHIKAWA is one of the businesses still working according the traditional techniques. When in time of peace, the production of weapons, in which the family was specialized, became redundant, they switched their production to beautifully crafted daily-use items instead. The business is still run by the same family today and are well-known for their high-quality products which they sell from their small workshop and shop in the center of Odawara city.

They produce simple, yet elegant day-to-day products that capture the tradition of the Odawara lacquer art as well as the turnery techniques.

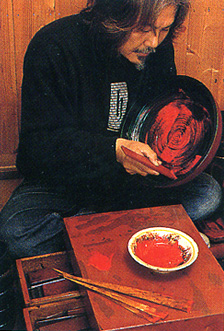

Mr. Ishikawa is recognized by the Japanese government as masters of the lacquer-applying craft. His style of applying lacquer initially produces a matte, rather than shiny finish, as he suggests the item will gain a natural shine the more it is used, and that they should therefore be used and washed often.

That natural change reflects the item’s history and allows the user to be part of the production process.

The skill to successfully applying several layers of lacquer is said to take about 10 years to attain. These traditional methods have been handed down for centuries and Mr. Ishikawa is one of the traditional craftsmen who still know how to apply them.

Production process

The first step in the production process is creating the wooden base. The plain, characteristic and high-quality wood that forms the base for the Odawara lacquer mainly comes from Keyaki, a Japanese zelkova. Alternatively, Kalapanax, Mulberry and Horse chestnuts are used, depending on the usage and size of the final product. Whereas this wood used to be collected from Hakone, artisans now get it from Northern Tokyo as the forest in Hakone was turned into a National Park.

The process starts with blocks of wood that, after harvesting, have been left to dry for about one year. In the traditional method, a lathe is used to shape a block into an object, a step that requires years of experience and is a designated traditional craft in its own – the craftsmen who specialize in this are different than the one specializing in the lacquer application. The wood is shaped based on a drawing, using a circular saw that first makes a rough shape. Once the desired shape has been cut, it is dried in a smoke dryer for 3 to 4 days after which it is coated with glue to prevent it from cracking.

Next, it is dried in an electric dryer for about three weeks and then naturally dried for two months up to a year. This long process is to make sure all the moisture is removed from the wood to avoid cracks over time. The dried wood is then shaped into the intended final product shape using a potter’s wheel for round shapes, or a router for more complex ones. Once smooth, water is applied and the shape is policed using horsetail plant.

Next, the raw lacquer is painted on the wooden base. There are two ways of doing this; “Print-painting lacquer” is a technique that accentuates the beauty of the coarse grains by covering them with a thin layer of raw lacquer. The process of coating and polishing is repeated for about seven or eight times, until the surface of the lacquer is smooth. “Polish painting wood grain” is a technique where a raw lacquer called ‘suki urushi’, or transparent lacquer—which has water removed to increase its transparency—is painted on the wood grain. Thus, the coarse grain is not covered, and can be seen in its genuine form. This results in products that are durable and experience minimal warping.