KANERYO provides a full overview of their processes and is dedicated to offering their customers full transperancy to instill trust and an interest to the process of sourcing and producing their beloved foods.

Sea Vegetables

Sea Vegetables are a very healty, tasty food with various nutrients and benefits - including dietary fiber, minerals and low calroies. It grows by absorbing the rich minerals dissolved in seawater and therfore is a concentrated source of nutrients from the sea. In Japan, sea vegetables have been an important part of the Japanese kitchen for many years, being used in soups, salads, and many other dishes.

Some of the benefits and conditions of sea vegetables have only been discovered recently and there is much more to learn. KANERYO is one of the few “sea vegetable specialists” in the world to help discover these.

KANERYO

Since its establishment in 1954, KANERYO has been a pioneer in the field of sea vegetable and a comprehensive manufacturer, from basic research to product development, manufacturing and sales. They have become the No. 1 sea vegetable manufacturer in Japan, with advanced manufacturing technology, quality control, and stable supply. Whereas most businesses specialize in one or two sea vegetable products, such as wakame or hijiki, Kanreyo handle everything from popular colored sea vegetable to rare species. They furthermore develop and manufacture salted- and dried products for consumers to enjoy in different types of dishes. This makes them a pioneer in the sea vegetable industry.

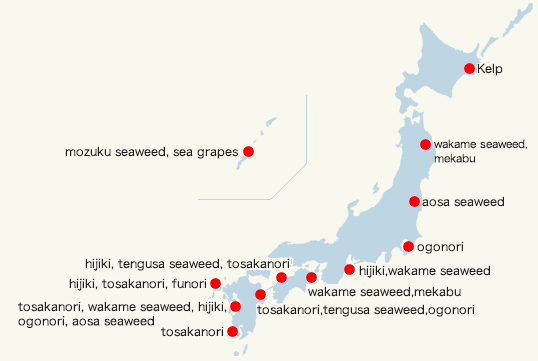

KANERYO's production areas

"From the Sea to your Plate"

Sourcing and producing fresh sea vegetables requires a combination of human skill and passion.

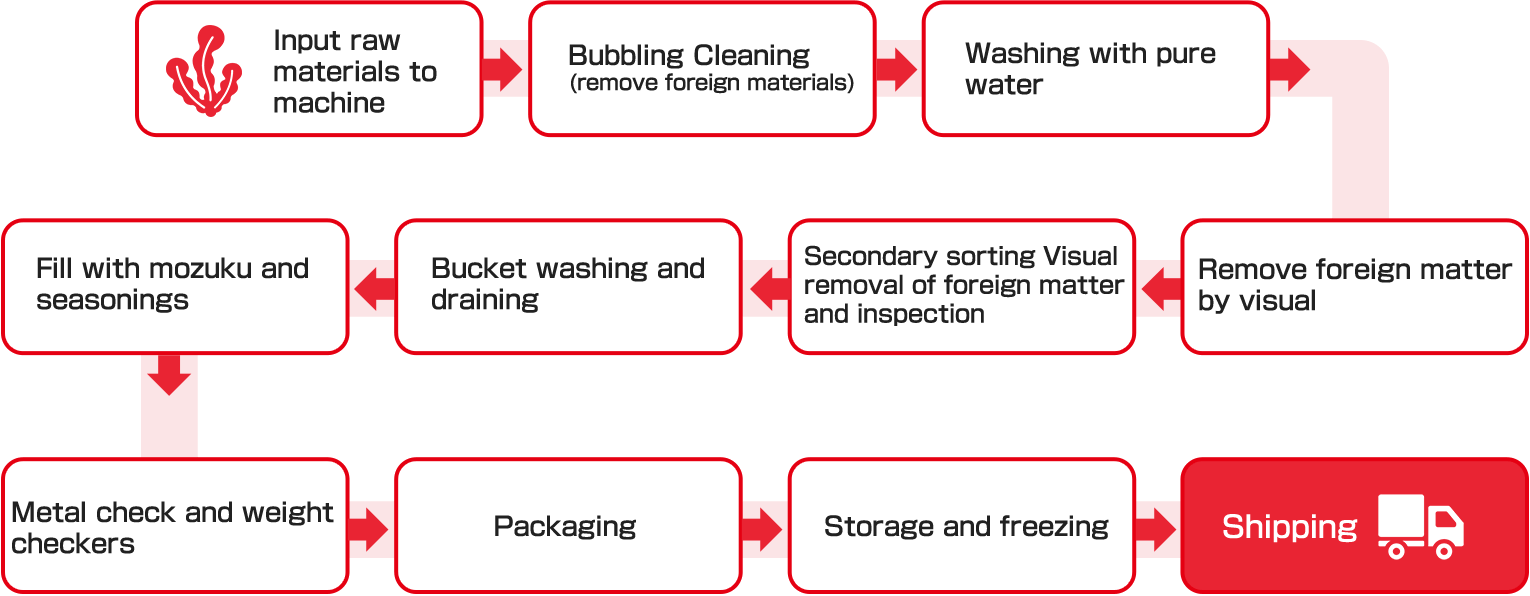

As it is an all-natural product, sometimes small sea creatures, stones, or shells are mixed in with the harvest. The sorting process to remove these cannot be automated, and requires a patient and meticulous “human” touch. "The delicate senses of the human eye and fingertips are indispensable in identifying and removing of foreign matter."

To balance out this manual labor, KANERYO uses proprietary equipment and in-house developed manufacturing machines to be able to supply one of the highest production volumes in Japan, as well as answer to a growing demand from abroad. Despite them having achieved a very high level of automation, they emphasize that their workers' talent is the driving key behind their business and they are very dedicated to their employee education system and ensuring employee satisfaction.

Production Process & Safety

Important tests such as microbiological and physicochemical tests are part of KANERYO's dailt operations.

Their safety and hygiene management procedures are created with the customer's point of view in mind, to ensure making delicious, safe foods and offering transperancy for customer's peace of mind. They carry out hygiene surveys of fisheries companies and contract factories that purchase raw materials in cooperation with the manufacturing department, visiting all partners from Hokkaido to Okinawa for inspection.

Quality Control Steps

Raw material control

Microbiological inspection and quality confirmation inspection at the time of receipt and use.

Product control

1. Physical and chemical inspection by liquid chromatography (HPLC), pH meter, Brix meter, etc. for each manufacturing lot, etc. at the time of manufacturing.

2. Microbiological inspection of each production lot after production, keep sample retention.

Manufacturing process and equipment control

Sampling and wipe inspections by process and equipment.

Control of additives etc.

Control of quantity and prevention of misuse.

Employee management

Education and guidance on hygiene. Shelf life control. Shelf life inspection for setting shelf life. Document management and preparation. Product specifications, labeling checks, etc.