See here how the Edo windbells are blown by hand and dyed from the inside!

SHINOHARA

Edo Furin literally means "Wind bell from Edo". During the 18th century glass making techniques got introduced in Japan by the Dutch, who were the only traders accepted in the port of Nagasaki. From there, the then-expensive glass was traded to the most affluent parts of Japan, including Osaka, Kyoto and Edo (now Tokyo). Once the local craftsmen mastered the art of making glass wind chimes, they became available to the general public and developed more and more variations.

When the Shinohara family started their business specializing in handmade wind chimes 65 years ago, they decided to name it Edo Furin to cultivate the traditions and appreciation of the chimes during the Edo period. The bottom of the hand-blown Furin is left uneven so that the chime makes different sounds depending on where the pin hits the glass. These details make the hand-made, traditional crafts authentic and unique.

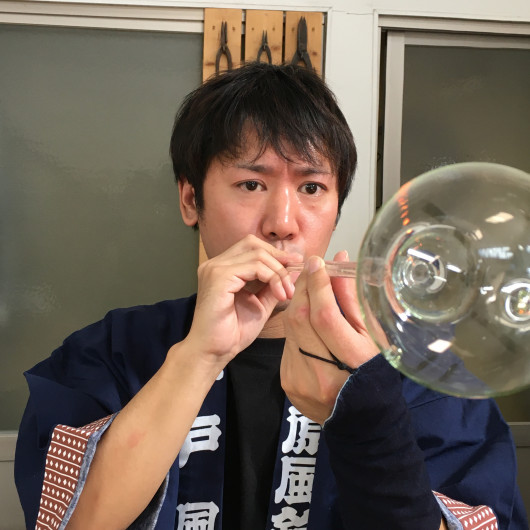

Each wind chime is hand blown and hand painted and a small piece of art by itself. Glass is melted in a furnace at 1320ºC after which a craftsman will blow two bubbles out of the glass. The first one is the main body of the wind chime, whereas the second, smaller one is broken off after cooling down. As a result, the hole at the bottom of the chime has uneven borders, which are left like that intentionally! This way, the chime will create different sounds based on where the bell touches the glass. Industrialized versions will be smooth and even, but will only create one monotone sound.

The decorations are hand-painted from the inside of the glass. This technique requires about 30 years of training, but it results in a great shiny chime, which' colors don't easily fade and are not affected by dirt, water and sunshine.

The Shinohara Team

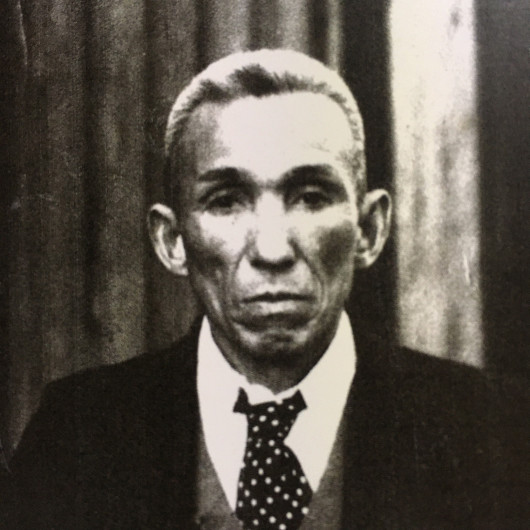

Founder

until 1970

Second generation

until 2021

Third generation (current leader)

Wife third generation head painter

Glass blowing craftsman

Painter

Glass blowing craftsman

Mascot "Kuromaru"