MORIHAN has a rich history of over 120 years, allowing them to make exceptional nori.

Nori is a type of crispy seaweed that has been served since the early Edo period (1603 - 1868).

The seaweed is cultivated from fresh water containing plenty of nutrients. During WO2 fishing was almost impossible due to the air raids, but ever since the industry has recovered and high quality brands source their nori from the best areas in Japan.

Morihan Nori, est. 1901

Japanese Nori is a key ingredient in the Japanese kitchen that has become well-known all over the world through their essential part of traditional “sushi” dishes. However, there is much more to the art of nori than just holding sushi and onirigi rice balls together. Morihan was established in 1901 and has shared their passion for nori for many years. Next to making excellent nori, they organize workshops to educate children and aspiring craftsmen in the traditional art of making nori.

Company History

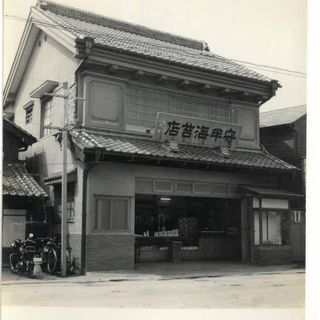

Moriya family in front of their first store

Ms. Chisako, 4th generation leader

Founder Moriya Hansuke opened his first shop in 1884, but would only establish the official Morihan brand in 1901. The family formed a strong team from the beginning with the eldest son initiating the roasting of "hoshinori", which would become a popular item, and the eldest daughter opening a nori retail business.

They realized yaki nori (roasted nori) could be stored in tea containers to be preserved longer and sold it as such, resulting in their high quality nori to become a popular local souvenir. Slowly, their nori became famous all over the country.

Over time the company has faced many challenges. The store and family home were damaged severely in the Great Kanto Earthquake (1923) and their homes and stores were completely destroyed by air raids on Tokyo, during WO2. This forced them to rebuild their shops and make improvements where possible.

Many years later, they celebrated their 115th anniversary in 2016 and announced to be looking forward on 100 more years of sharing their love for nori with the world!

They have since been awarded and featured in several initiatives such as "the best souvenirs" and "food selection corners" and have set up internship and graduate programs to encourage young people to learn and succeed in their art.

Their current motto is: "Strive to be a company where our customers, employees, and their families can be happy together."

MORIHAN Prodution

Freshly harvested seaweed comes in every year in January. It arrives while it’s still moist and gets stretched and dried in Morihan’s special underground factory. One large piece of seaweed (equal to approximately 100 sheets of nori seaweed) is spread, lightly folded in half, divided into 50 pieces, and wrapped. The nori is checked for its quality by specialists. Being a natural product, each sheet will have a slightly different quality, and Morihan ranks them according to grades, based on their experience of working them. The final quality depends on, especially, three things: the place of harvesting, the nori craftsmen, and the date of harvesting. Morihan is particular about the very firstly harvested batch, as this will result in premium texture and flavor.

After being sorted, the sheets get lined up in what is called a “roaster”, to carefully dry.

Many contemporary producers use a hot air fan, which will quickly spread air and speed up the drying process, but Morihan works according to traditional methods, using an electric heating roaster with 5 different shelves: The nori slowly, and carefully dried and moved down a shelve after careful inspection every half-day. The process takes 2,5 days. As the seaweed is dried very gradually, the original flavor and strong umami remain and come through perfectly in the final nori sheets. As seaweed is a living algae, no matter how skillfully they handle the base ingredient, the flavor profile and exact taste will be different every year. The company organizes intense tasting- and training sessions each year to best determine the production and understanding of that year’s nori.